29 Jul Cold Formed vs. Machined Nozzles: Which Offers Better Cut Quality and Speed?

The performance of plasma and laser nozzle consumables determines the precision of cuts along with operational efficiency and production expenses in precision manufacturing. Whether making automotive parts or intricate aerospace components manufacturers depend on durable and accurate nozzles that ensure production operations remain uninterrupted.

Traditionally, machined nozzles have been the first choice. Machining is a well understood and mature process. Most production engineers are familiar with it, and it is available in a wide range of manufacturing industries. However, new developments in cold forming technology are revolutionising the way nozzles are designed and built – with measurable benefits to cut quality, feed rates, tool life and cost.

In this blog we are going to look at how do cold-formed nozzles compare to standard machined nozzles, and which one gives you better cut quality and speed for your operation?

What Is the Difference Between Cold Forming and Machining?

Machining is a subtractive process. Material is cut away from a block to create the part geometry. This means there are a few fundamental disadvantages to this process:

- Internal surface finishes will have small tool marks, creating a slightly rougher surface.

- Sharp corners and stepped profiles can generate turbulence in the gas flow.

- Material waste is relatively high.

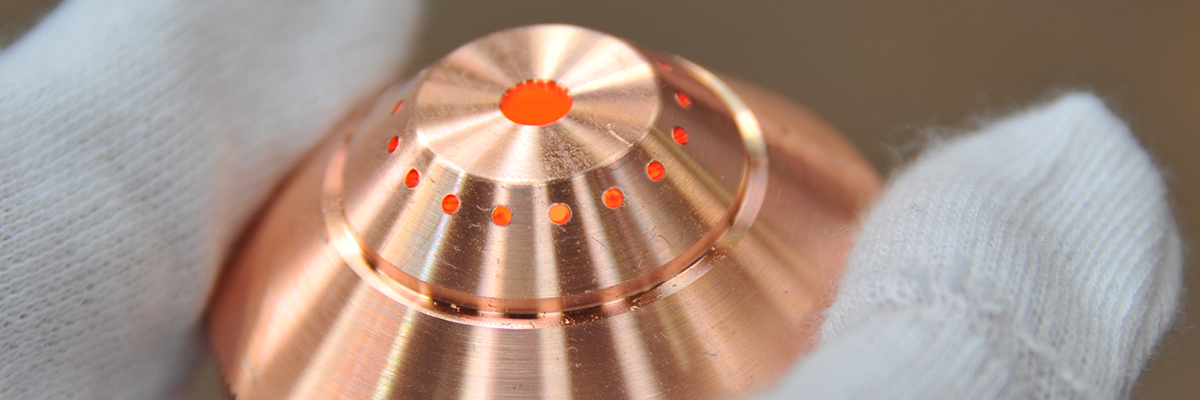

Cold forming is a forging process, so the part is pressed at very high pressure out of raw material in a forming die at room temperature. The process deforms the material instead of cutting away chips, and the displaced material is forced into the geometry of the nozzle:

- This creates a much smoother internal surface finish, around 0.1µm compared to 1µm for a typical machined nozzle.

- It also benefits grain structure and material strength by deforming the material in the forming process.

- Less material is wasted compared to machining, making it a more sustainable process.

This key difference between these two processes is the foundation for further performance advantages.

Why Surface Finish and Geometry Matter

The velocity and consistency of the gas flow through the nozzle is essential when cutting with a plasma or laser system. Internal nozzle turbulence or obstructions can have a detrimental effect on gas speed and consistency, leading to:

- Variable kerf widths

- Sub-optimal edge quality

- Dross and unnecessary heat input

The smooth bore and optimised curved profile of a cold-formed nozzle results in a smoother gas flow with an internal surface akin to a mirror. The result is not only a more stable, precise and accurate cut, but reduced heat-affected zone and less post-cut finishing.

Performance in Cut Quality

Cut quality is generally quantified in terms of edge quality, amount of dross, and process repeatability over lengthy production runs. To compare side-by-side:

- Machined nozzles are acceptable but may have micro-defects in the cut from tooling marks that worsen at high cutting speeds or after long service intervals.

- Cold-formed nozzles result in a cleaner edge, less dross, and repeatable performance over time due to higher internal finish and stable gas flow characteristics.

In turn, this means less grinding, deburring, and re-cutting for manufacturers – an immediate labour and process cost savings.

Performance in Cutting Speed

Possibly the greatest benefit of cold-formed nozzles, however, is the opportunity to boost feed rates by as much as 10% to deliver improved cut quality without loss of precision. That translates to:

- Higher throughput and productivity

- Shorter cycle times

- Speedier order fulfilment

This can be a major competitive advantage for production managers who are always under pressure to meet deadlines and optimise machine uptime.

Durability and Operational Life

By refining the grain structure of the material, cold forming can result in a cold-formed nozzle having improved wear resistance and better part strength than a machined nozzle. This means:

- Longer time between nozzle changes

- Less chance of downtime due to consumable failure

- Less inventory required for spare parts

- For multiple shift or around-the-clock production, extended nozzle life can equal thousands of pounds in annual savings.

Cost Savings and Sustainability

Cold-formed nozzles provide not only the direct performance advantages described above, but also other indirect benefits. They offer:

- Reduced machining time and post-processing: The nozzle is formed, not cut, so there are fewer finishing operations, and the part is ready to use right out of the machine.

- Lower material waste: Cold forming is a very efficient process, with little to no scrap material when compared to machining.

- Less clean-up after cutting: Improved cut quality means less grinding or finishing work for operators, which is energy-efficient and reduces the environmental footprint.

- When combined, these factors can not only reduce the cost of production, but also meet the requirements of today’s environmental, social and governance (ESG) efforts.

Making the Right Choice for Your Business

Machined nozzles have worked well for many years. But as production rates and tolerances increase, cold-formed nozzles are becoming the nozzle of choice. If you are cutting sheet metal for automotive parts, precision aerospace components, or packaging products, cold-formed nozzles will provide:

- Safer, faster cuts

- Longer nozzle life

- Reduced total operating costs

Cold-formed nozzles (CFN) versus machined nozzles

The benefits are numerous when it comes to the quality of your cut, increased cutting speeds and longer life, all with a notable reduction in cost. But it doesn’t stop with the cut quality. There are far-reaching effects on the entire production process. These can be seen in a wide range of cost savings from lower maintenance, reduced clean-up, faster production throughputs, and more.

Case Study: YAG Laser Nozzles

YAG laser systems have seen increasing use recently since they can produce precise cuts at a lower price point than their more involved five-axis CO₂ laser gantry counterparts. YAG laser nozzles are conventionally difficult and expensive to machine because of their long-tapered bores.

Extensive R&D has allowed us to create cold-formed YAG nozzles up to 75 mm in length. Achieving a superior internal finish and good dimensional tolerances over such a length was one of the major hurdles in producing high-performance consumables for this fast-growing market.

Advantages for the customer include:

- Better cut quality and repeatability

- Higher feed rates and throughput

- Considerable cost savings over machined alternatives

Interested in learning more?

Get in touch with us to discuss your application and discover how our precision engineered, cold-formed nozzles can offer your business a competitive performance advantage.