29 Oct Power generation components – which process to choose between Cold Forming and CNC Machining?

Power generation components – which process to choose between Cold Forming and CNC Machining?

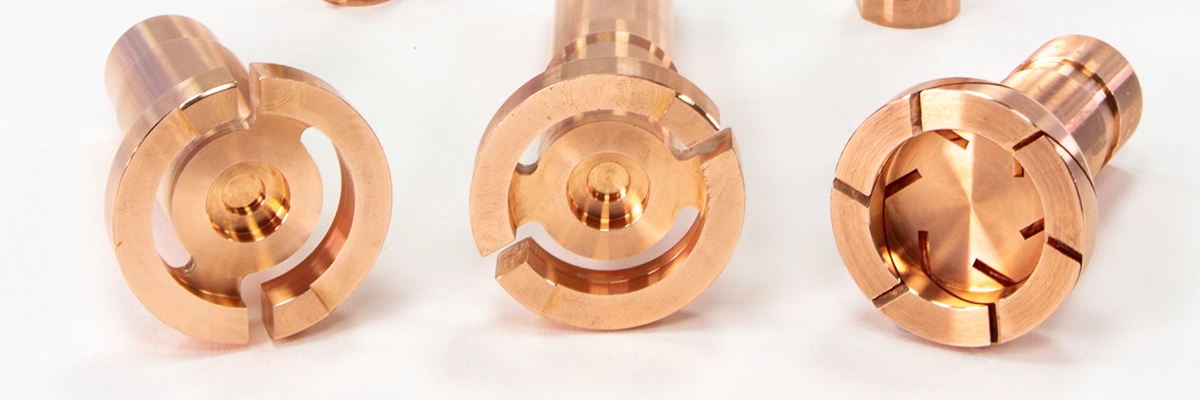

Precision components used in power generation and distribution systems can be manufactured through several methods, two of which include cold forming, and CNC machining. Both methods have their place in the production of quality components, and a few factors go into deciding which will work best for a particular part. Factors such as the component design, the material or materials used, and the required performance of the finished part can all have an impact.

Selecting which is best for a given application isn’t just a matter of cost, but one of efficiency, precision and long-term dependability as well. In this blog post we will compare the two processes to one another and help you decide which is best for your next high-power project.

Basics of cold forming

In cold forming, we work with metal at or near room temperature. It can be done by applying very high pressure to shape the material without removing any metal. Compression forces shape the metal into the needed form with the use of specialised tooling and dies.

By contrast, CNC machining (Computer Numerical Control machining) involves removing material from a solid billet using cutting, drilling, milling, or turning operations directed by a computer. It’s best for very tight tolerances and complex geometries.

Cold forming deforms metal. CNC machining cuts metal. Both are extensively used in the manufacturing of connectors, contacts, terminals and fittings for power generation and distribution equipment – where conductivity, strength and reliability are critical.

Cold Forming: Strength, speed, and sustainability

Scraps are usually less than 1% because the material is displaced rather than sheared off, as opposed to up to 50% in conventional machining. This is one of the main reasons why cold forming is a more sustainable process. This benefit is further compounded when working with more expensive materials. Oxygen-free copper and other copper alloys are commonly used for electrical applications and are often subject to cold forming.

Benefits of cold forming include:

- Better mechanical properties: Work hardening makes the products stronger and more durable without requiring heat treatment.

- Excellent surface finish: No cutting tools are used, resulting in smoother surfaces and requiring fewer secondary finishing operations.

- Cost effective for volume production: Rapid and repeatable production runs, particularly once tooling is established for medium-to-high volume production.

- Environmentally friendly and less waste: Minimal scrap and lower energy consumption, and tool life as compared to machining.

These benefits mean cold forming is especially well-suited to high-power connectors and terminals, where high conductivity needs to be combined with mechanical strength, in power generation and distribution systems for example.

Cold forming is not suitable for every design; it works best when the components to be formed have simple geometries or can be designed with forming in mind. That’s where Design for Manufacture (DFM) comes in – engaging with engineers at the early stages of design can help optimise components for forming, without loss of performance.

CNC Machining: Accuracy and flexibility

For tight tolerances, complex geometry or low production volumes CNC machining is usually still the preferred process. CNC machining is the most accurate and flexible process.

Benefits of CNC machining:

- Can achieve tight tolerances or fine features.

- Can produce deep internal features, threads, and complex geometries without secondary tooling

- Prototyping or small production runs for which tooling costs must be minimised

- Versatile enough to machine most metals, including many high strength alloys and exotic materials

In the power generation industry, CNC machining is used for complex housings, connector bodies, and other custom fittings in which repeatability and accuracy are critical. It can also be useful for machining modifications to formed components, or in situations where both formed and machined features are needed on the same part – so-called hybrid parts.

The obvious drawback of CNC machining is the time required, as well as the wasted material. As a subtractive process, CNC machining turns metal into chips – that is, waste material that you pay to discard when you’re working with precious metals like copper. The process is also much slower when large quantities are needed.

Which process Is right for Power Generation components?

The decision between cold forming and CNC machining is usually based on a few important factors:

| Factor | Cold Forming | CNC Machining |

|---|---|---|

| Production volume | Best for medium to high volumes | Best for low volumes and prototypes |

| Geometry | Suited to simpler, axially symmetric parts | Ideal for complex or irregular shapes |

| Material waste | Minimal | Moderate to high |

| Tolerances | Excellent, but limited by forming capability | Extremely tight tolerances achievable |

| Surface finish | Smooth, often near-net shape | Excellent, with post-processing options |

| Cost efficiency | High once tooling is in place | Higher per-unit cost at volume |

Power connectors, contacts, and terminals are typically best cold formed for optimal strength, conductivity and cost. However, housings, prototypes or parts with complex geometries are often required to be CNC machined.

The hybrid approach: Best of both worlds

At Luvata Welshpool, we frequently utilise a combination of the two. In some instances, it is advantageous to cold form a component to a near-net shape for the best material utilisation and maximum material strength and then machine finish it to achieve close tolerances and/or add difficult-to-form features.

This combined process offers our customers in the power generation and distribution markets the best of both worlds, including:

- Less material cost

- Enhanced mechanical and electrical performance

- Quicker lead times

- Repeatable quality

Cold forming and CNC machining are not competing processes but complementary tools in the engineer’s toolkit. By selecting the right method – or combining both – you can achieve the perfect balance of strength, conductivity, precision, and price.

To discover how Luvata Welshpool can improve your components through cold forming, CNC machining or both, please contact our team of engineers. We’ll work with you from concept to completion and make sure each component performs perfectly where it matters most.